New research released by Asialink Business, in partnership with Toll Group, looks at the pressures on global supply chains, most notably highlighted by the challenges of COVID-19. Asialink Chair Peter Varghese AO and Thomas Knudsen, Managing Director of Toll Group, argue technology, innovation and e-commerce will be key to building resilient supply chains in a post-COVID world.

COVID-19 has shone a spotlight on the arcane world of supply chains. From shortages of toilet paper to timber and semiconductor chips, businesses and consumers in Australia and globally have all experienced first-hand the disruption to international supply chains over the past twenty months.

New research released this week by Asialink Business, in partnership with Toll Group, looks at the structural pressures on supply chains exacerbated not only by COVID-19 but also geopolitical tensions and extreme weather events. It indicates that technology, innovation and e-commerce will be the key drivers of building resilient and sustainable supply chains.

The latest trade statistics released by the OECD in late August paint a global picture where soaring commodity prices are driving overall merchandise trade to new highs, whilst congestion in international shipping and supply issues places pressure on traded goods.

These rolling crises have driven many businesses to rapidly shift away from lowest cost, which brings with it often long and complex supply chains towards shorter, regional alternatives as well as increase inventories. Building this resilience into supply chains comes with costs that are putting pressure on profits.

In a post-COVID-19 world, business will need to think carefully about how it balances resilience and cost-effectiveness, as well as how to keep up with emerging technologies that are driving transformation.

China and North Asia leading the pack in supply chain technology

Technology is revolutionising supply chain management. The Internet of Things (IoT), machine learning (ML), artificial intelligence (AI) and improvements in data analytics are helping businesses increase manufacturing productivity, improve logistics, and provide tailored customer experiences.

This is a global phenomenon. But access to deep pools of capital and supportive government policies mean adoption in North Asia is particularly rapid.

China’s Cainiao — the $10 billion logistics subsidiary of global e-Commerce giant, Alibaba — offers a standout example. Cainiao’s IoT platform integrates the business’ storage facilities with one of the world’s largest fleets of autonomous vehicles. The company has invested heavily in infrastructure and grown quickly. Using cloud computing to connect with over 3000 logistics and delivery partners, Cainiao can now deliver a one-kilogram package anywhere in China in 24 hours, for approximately 40 cents.

E-commerce is creating opportunity, but also supply chain pressure

This rapid and reliable delivery shows how e-commerce is reshaping consumer expectations around speed, convenience, and personalisation. Customers now want access to a wide range of products, delivered quickly, with easy options for returns. They increasingly seek a unique and personal service, such as special packaging for high-end retail.

The COVID-19 pandemic has accelerated Asia’s e-commerce boom. Spurred by rising incomes and growing internet and mobile penetration, Asia’s e-commerce market grew by almost 20 per cent between 2019-2020, and is forecast to reach $3.3 trillion by 2024.

But as the region’s e-commerce volumes grow and consumers' expectations evolve, traditional supply chains are being put to the test. Businesses that fail to invest in an agile, digitally connected supply chain will risk losing market share to competitors that can better fulfil these consumer needs.

Supply chain technology & sustainability

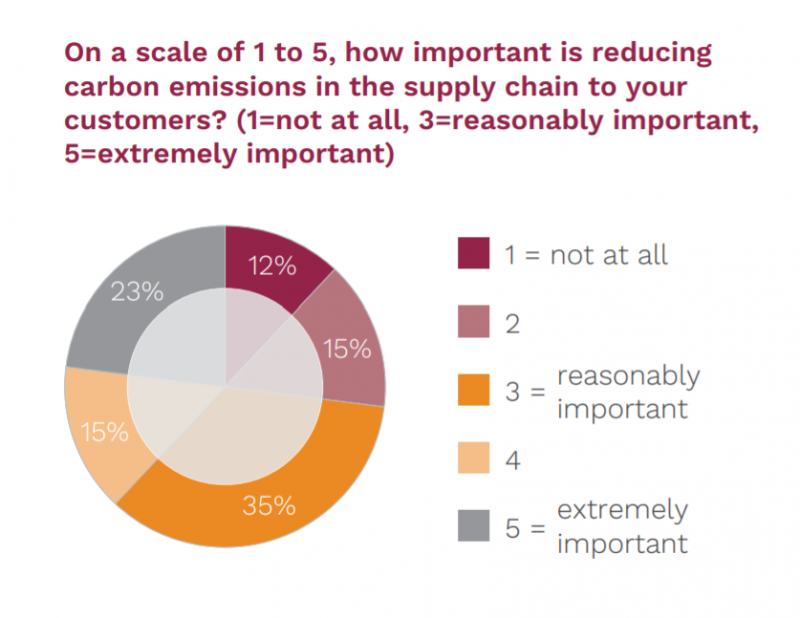

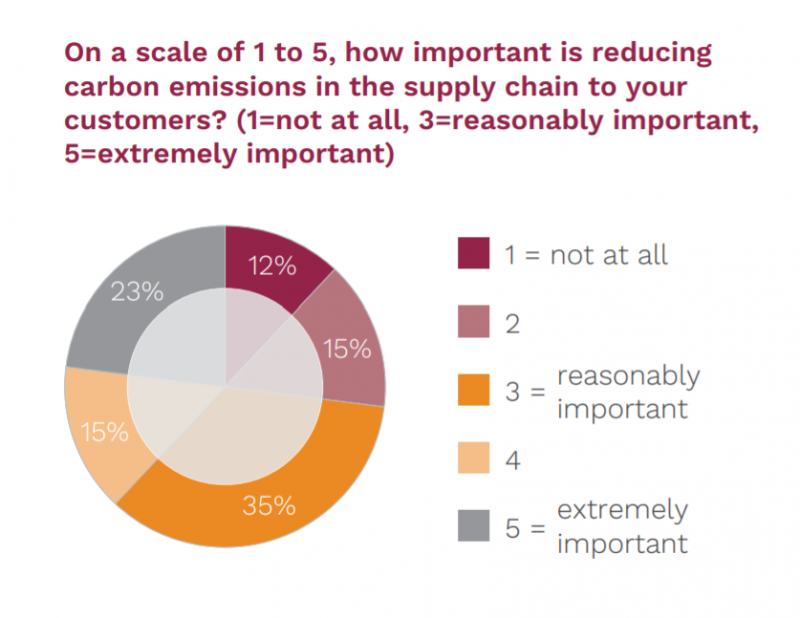

To varying extents, customers, investors, and regulators across the Asia-Pacific are also expecting businesses to do more to demonstrate sustainability. This creates challenges, as most businesses have diminishing visibility of suppliers further up the supply chain.

New technologies, in particular improvements in data management driven by AI and ML, are helping responsible business address these challenges and meet rising consumer and social expectations around sustainable production and distribution.

Asialink Business/Toll Group research highlights the importance of reducing carbon emissions in the supply chain to customers. Image credit: 'Disruption & Innovation: Reshaping Regional Supply Chains' – Asialink Business and Toll Group.

New technologies are providing greater visibility and transparency, in addition to efficiencies. Take the example of Japanese clothing retailer, Uniqlo. The company has focused on reducing carbon emissions in manufacturing in its sustainability strategy. It has pioneered filtration technology to make polyester fibre from recycled plastic bottles. This process generates approximately one third of the carbon emissions used when polyester is produced from crude oil, thus significantly reducing Uniqlo’s carbon footprint.

Australian business has made some progress, but risks being left behind

The rapid adoption of new supply chain technologies across Asia will create new opportunities for Australian businesses that are equipped to connect with them.

But business has been reluctant to embrace these innovations on a large scale.

Cost is still a significant restraint. Although the price of advanced technologies has fallen considerably in recent years, businesses require significant capital to establish and maintain autonomous systems.

The barriers are particularly acute for smaller and medium businesses. For example, the Asialink Business/Toll survey found that 27 per cent of medium business, and just 13 per cent of small business are investing in AI for supply chains, compared with 47 per cent of big business.

Put simply, if we are to compete successfully in Asia’s fastest paced markets, we will have to invest more in resilient and sustainable supply chains that meet the shifting needs of customers in Australia and globally.

Finding supply chain partners with extensive experience in the region can help businesses of all sizes keep up with rapidly evolving technologies and standards. Partnering with organisations with deep experience in the region doesn’t just help business identify and manage supply chain transparency. They can also help business identify and seize on new opportunities created by the roll-out of new infrastructure and the expansion of e-commerce platforms across Asia.

Asia is not a homogenous market in its own right, with different countries bringing unique challenges – and opportunities. Agility and nuance is important to navigating current challenges and unlocking future opportunities.

Peter Varghese AO is the Chair of Asialink and former Secretary of the Australian Department of Foreign Affairs and Trade.

Thomas Knudsen is the Managing Director of Toll Group, with more than 25 years’ experience across the global transport and logistics industry.

Banner image: Aerial view of container cargo ship. Credit: Avigator Fortuner, Shutterstock.

This article originally appeared in The Australian ($) on September 20, 2021.